|

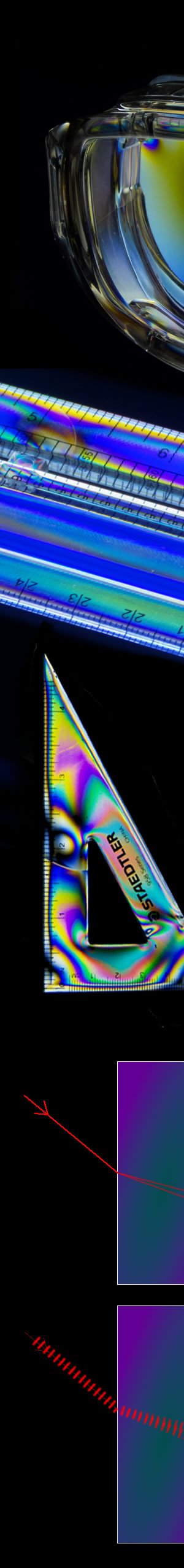

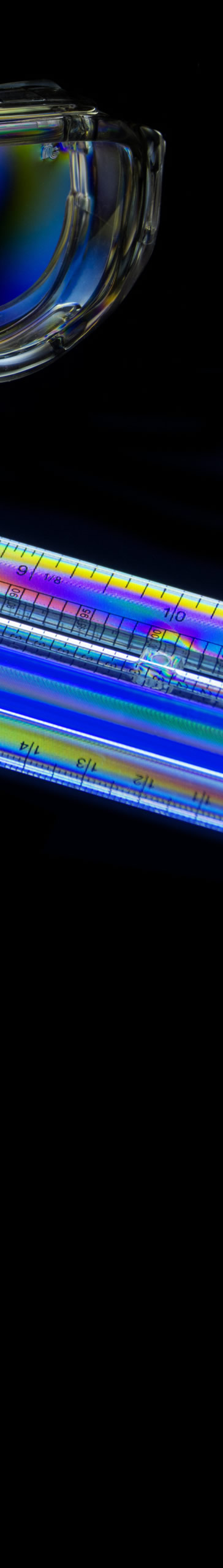

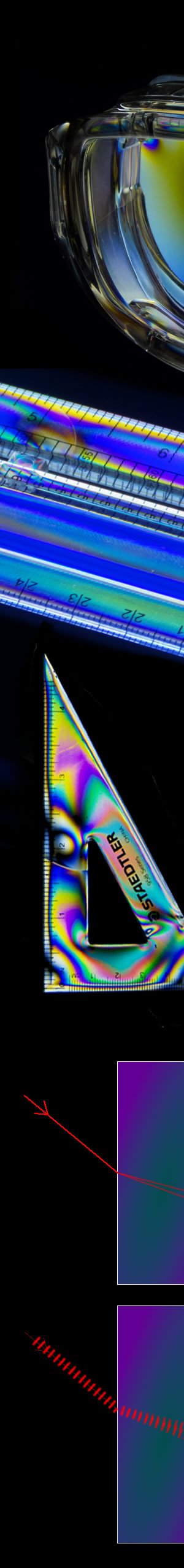

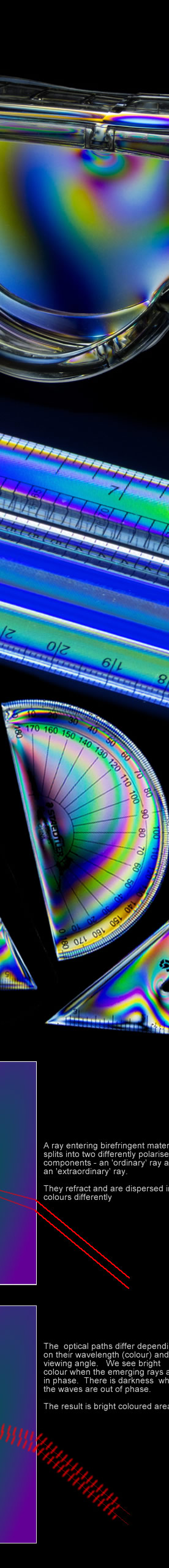

Thermoplastics have long molecules that are independent and not cross-linked to others. When strained during extrusion, moulding or sometimes when cold these long molecules can be partially aligned. The plastic then has properties – including optical characteristics - dependent on direction, it is anisotropic.

Anisotropy yields birefringence.

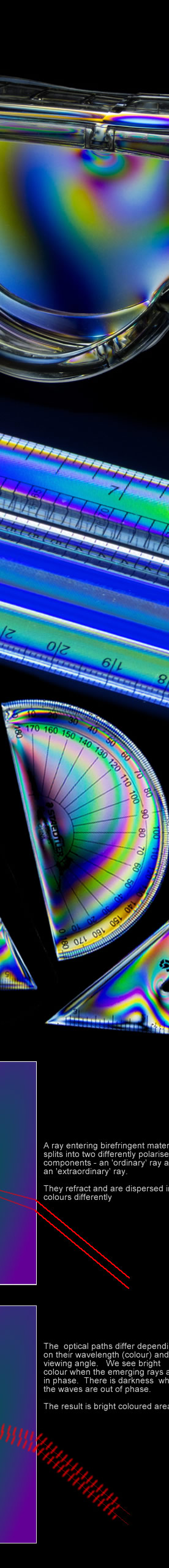

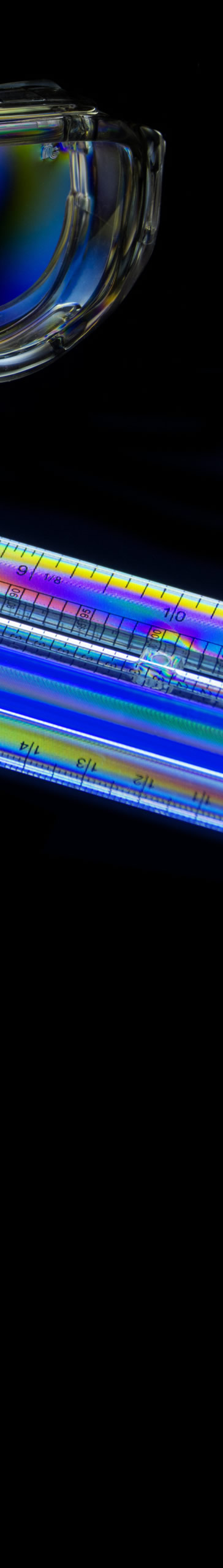

Little is seen with unpolarised light but when illuminated through a polarising filter and viewed through a second polariser, multi-colour patterns show the location and severity of stresses and strains.

A white LED monitor screen is an excellent polarised light source and a camera polarising filter or polarizing sunglasses a good viewer.

Place a transparent plastic object in front of the screen and view it through the polariser. The colours change as the object or polariser are rotated. The view is best when the two polarising directions are perpendicular and the screen appears black.

Try stretching or twisting a thin plastic sheet while watching the colours.

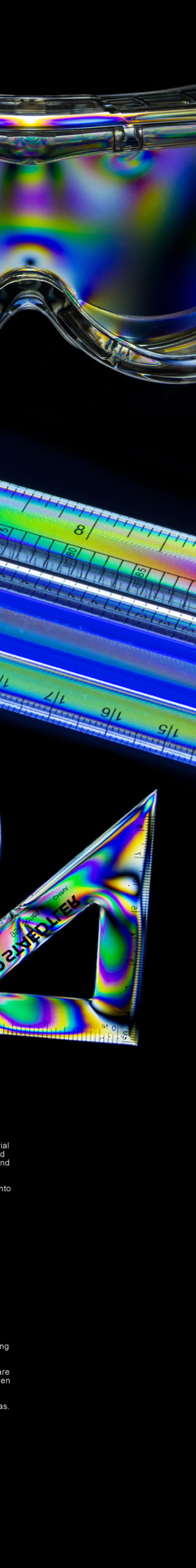

Birefringence -

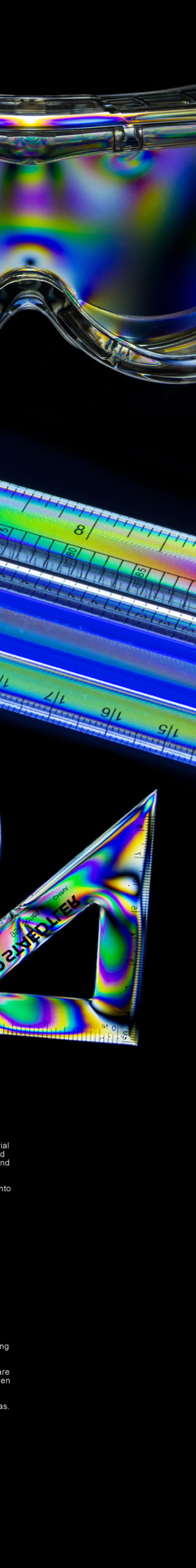

In the simplest type of birefringence the material splits light entering it into two distinct rays which are polarised and refracted differently.

The two rays also have their colours dispersed differently and this becomes apparent when the incoming light is first polarised and the emerging light is viewed through a second polariser. We then see colour patches.

The colours are formed by constructive and destructive interference between the two differently polarised rays. The two rays have slightly different optical path lengths as they traverse the plastic. On emerging, their wave crests can be in phase and combine to give a bright colour. They could also be out of phase giving less or no light. The phase condition depends on the wavelength (colour) and the viewing angle.

The result is patches of colour that show up the strain patterns. The phenomenon called photoelesticity is used to analyse stress patterns in materials although to some extent it has now been superseded or at least complemented by numerical methods.

|